Enter information about your punch in row d.

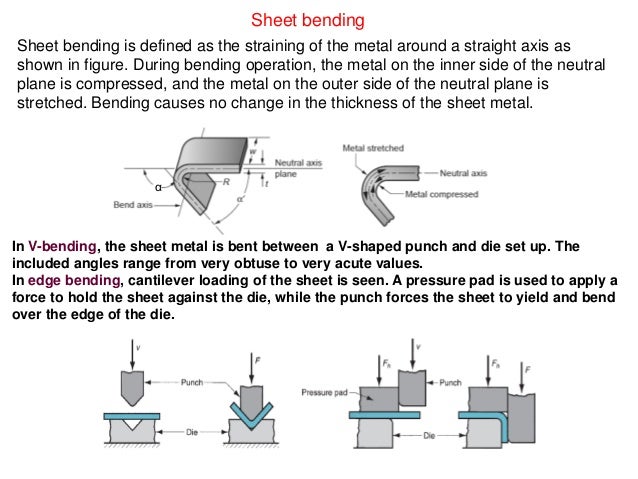

As sheet metal stock hardness increases the clearance between punch and die should.

This helps to prevent the punch from working into the die and minimizes.

The stress of high speed stamping can cause punches to work into the retainer damaging both the punches and retainer.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a.

20 3 as sheet metal stock hardness increases in a blanking operation the clearance between punch anddie should be a decreased b increased or c remain the same.

Increased 16 7 a circular sheet metal slug produced in a hole punching operation will have the same diameter as the a die opening or b punch.

Determination of the punch and die clearance value.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be increased a circular sheet metal slug produced in a hole punching operation will have the same diameter as the.

B a circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

The life of the mold is shortened.

Use it to calculate die clearance required for perforating metals plastics and more.

As sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

Enter information about the stock you are punching in rows a b and c below.

For more information please read proper die clearance.

Recommended punch and die clearance table see table 1 below the harm of too small clearance.

Increased a circular sheet metal slug produced in a hole punching operation will have the same diameter as a.

The die opening or b.

16 6 as sheet metal stock hardness increases in a blanking operation the clearance between punch and die should be a decreased b increased or c remain the same.

A circular sheet metal slug produced in a hole punching operation will have the same diameter as a the die opening or b the punch.

For the determination of the die clearance value empirical formulas and charts are generally used.

In any punching process you want as clean a cut as possible though it may be that the load required for a cut could increase and the.

I m not sure the hardness has that much of an effect on sheet.

The punching force increases.