This paint adhesion cross cut tester offers a high quality and precision engineered round shaped blade holder presenting selectable blades with 6 or 11 teeth and a.

Astm paint adhesion scratch test.

This procedure can also be administered on site and provides quantitative results in.

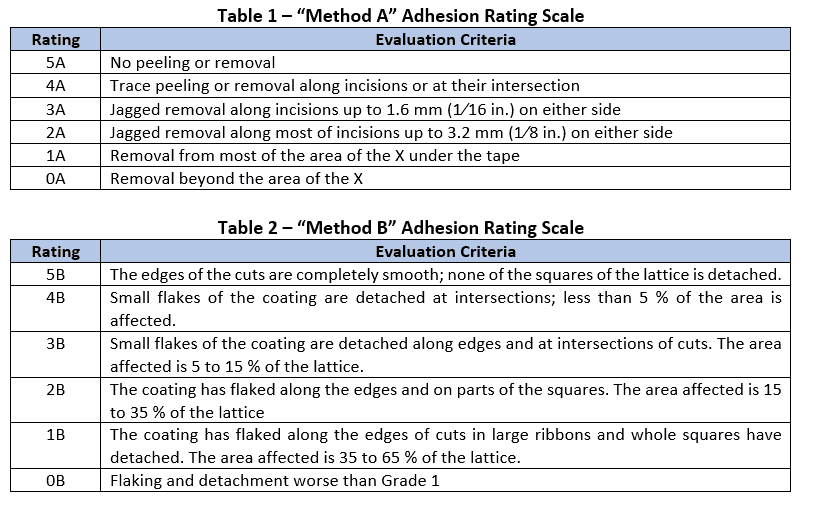

3 4 film adhesion test the coating film adhesion shall be tested in accordance with method b of astm d3359 09e2 standard test methods for measuring adhesion by tape test.

1 1 this test method covers the determination of the adhesion of organic coatings such as paint varnish and lacquer when applied to smooth flat planar panel surfaces.

Other related tape adhesion test methods include din en iso 2409 paints and varnishes cross cut test fltm bi 106 01 gm 9071p gmw14829 iso 2409 and navistar mpaps gt paint gt 5a.

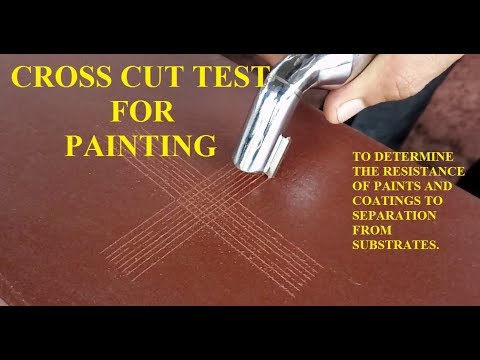

There are two variants of this test.

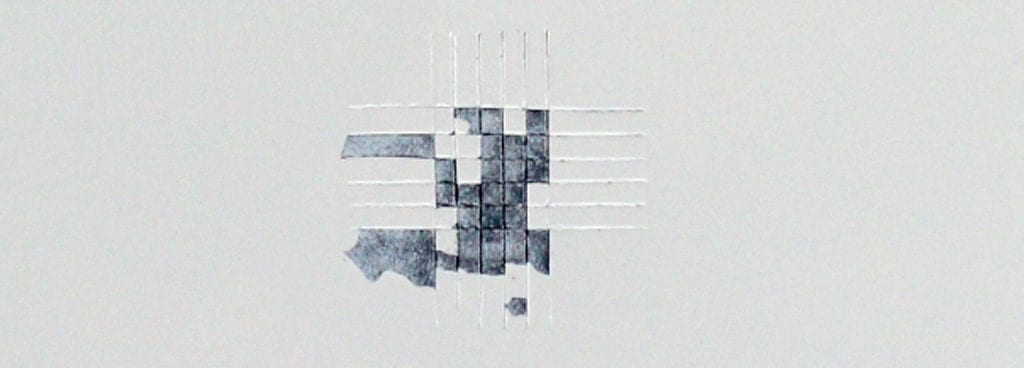

A total of 11 parallel cuts are made with a sharp instrument 1mm apart in both a vertical and horizontal direction forming a grid.

On metal substrates a more formal version of the knife test is the tape test.

The x cut tape test and the cross hatch tape test.

This test at the simplest level involves the examination of the paint film removed after an applied tape is peeled off.

Qualtech products industry cross cut adhesion tester cross hatch cutter is a professional instrument engineered to conveniently evaluate the adhesion performance of coatings applied onto specimen.

Pressure sensitive tape is applied and removed over cuts made in the coating.

5 2 the quantitative coating adhesion scratch test is a simple practical and rapid test.

Scratch test is one of widely used fast and effective methods to obtain the critical loads that are related to adhesion properties of coating.

As coatings continue to cure the adhesive properties will change.

This method assesses the adhesion of either one or multiple coatings on a smooth surface by applying tensile stress rather than shear stress measured in the previous two tests from a dolly to the surface the load is slowly increased until the dolly along with the adhesive layers is removed.

A standard method for the application and performance of this test is available in astm d6677.

Some coatings will improve in adhesion as the coating continues to cross link other coating systems decrease in adhesion due to different rates of shrinkage between substrate or coating layers within the system.

Functional behaviour of a coating is critical to its adhesion to the substrate.

Through the patterns and methods of astm d3359 17 s procedures adhesion can be much more easily and reliably measured.

1 2 the values stated in si units are to be regarded as the standard.

One inch wide pressure sensitive.

June 5 2012 4 scratch tests 1.

However reliable and reproducible test results require careful control of the test system configuration and testing parameters detailed analysis of the coating damage features and appropriate characterization of the properties and morphology of the coating and the substrate of the test specimens.